Together with its partners Momentive and BSC Computer, Dätwyler is launching dielectric elastomer actuators on the industrial market in 2024. They are covering the entire value chain, from raw materials to control of components for the drive technology.

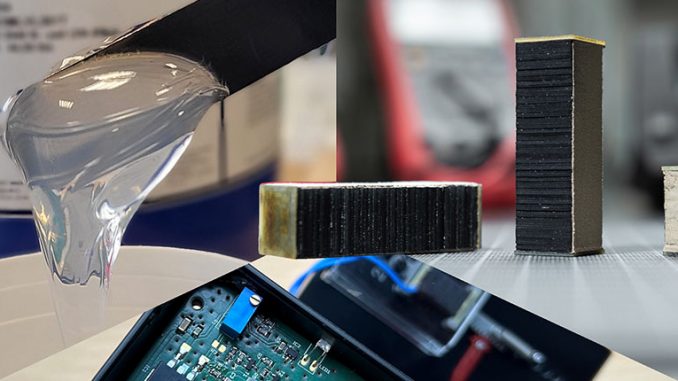

Dätwyler from Altdorf in the canton of Uri has joined forces with its partners Momentive Performance Materials, the German subsidiary of New York-based Momentive, and BSC Computer to cover the entire value chain of serial production of dielectric elastomer actuators (DEAs). According to a press release, Leverkusen-based Momentive is providing the base material: electroactive polymers (EAP). Dätwyler uses this to make the dielectric elastomer actuators, which will be produced in an in-house-developed facility from mid-2024 in Schattdorf in the canton of Uri. Electronic control units made by BSC Computer in Germany supply the actuators with the necessary high voltage and form an interface with the operator.

DEAs have previously been used predominantly for research purposes. They enable electrical signals to be converted into motion. The partners are now launching the energy-efficient components on the industrial market: for example, the technology can be used in the automotive industry and for medtech solutions.

“We are thrilled to offer our expertise in industrializing elastomer-based sealing solutions for the upcoming collaboration,” says Anette Wiesmath, Head of the EAP unit at Dätwyler. “Our individualized solution enables the production of stacked actuators across different application areas, presenting a unique technical advancement.”

Holger Albrecht highlights the potential of networking the EAP with the internet of things. “This collaboration enables us as a specialty materials manufacturer to gain insights into the use of our elastomers in end customer applications and to continuously optimize our material,” says the Vice President and Head of the Elastomers division at Momentive.

Courtesy of www.swisstrade.com